Investment Casting Original Equipment Manufacture

Investment Casting Original Equipment Manufacture

Generally, there are many Investment casting manufacturer company. but the top manufacturer of investment casting always gets many inquiries. They received progressed lost wax investment casting cycle for Original equipment manufacturer EM speculation casting to fabricate castings. For creation measure control, they have solid Technical dependability examination and improvement technique. 100% investigation for each interaction and progressed instruments (projector, tri-facilitator, spectra) help to deliver qualified castings.

About the OEM Investment casting

Top fundamental OEM Precision investment net projecting products are castings in treated steel, carbon steel, compound steel items serve for some exchange as food, substance, medication, marine, programmed, engineering, and so forth 90% for sending out to America, Europe and some Asia nations.

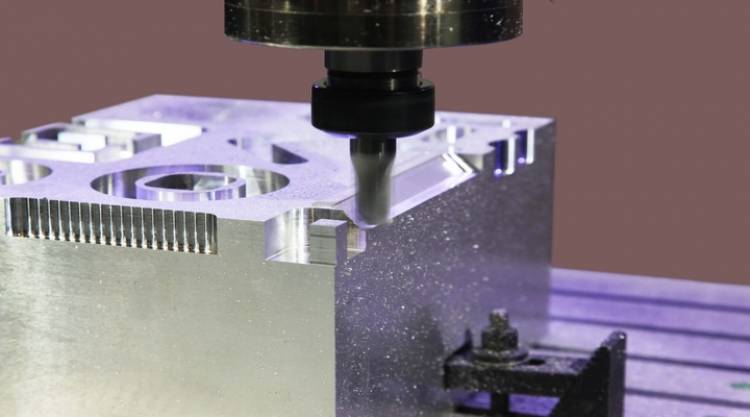

Primary machines for in the wake of giving interaction such a role as machining focuses, CNC machine, cleaning machine could supply machining, hand cleaning, get together.

Normally QC office and improvement office offer material examination, strength test, hardness test, wizardry powder test, and X-beam test. Tri-organize instrument and projector can assist with estimating careful measurements. In light of the immense assembling office network in China and the phenomenal production network of the executives, our OEM Precision investment business is under a fast turn of events. Exactness Machining in OEM investment casting, Used Method in investment casting is CNC(3D&4axis), lathe, milling, drilling, turning, grinding, polishing. The exactness can reach ±0.003mm, Control of the C.N.C. Electronic Numerical Control.

Further machining system work: turning and cutting, processing, pounding, penetrating and reaming, stringing

OEM Investment castings Utilization enterprises

They produce OEM Investment castings for the accompanying enterprises: Industrial apparatus parts, Marine equipment, Pipe Fitting Parts, Textile hardware parts, Sport office parts, Pneumatic instruments parts, Fluid gear parts, Copper combination parts, Food hardware parts, Automotive Parts, Elevator Parts, Air blower Parts, Electric machine and equipment fittings, Mining and earthmoving apparatus embellishments, siphon body and valve.

Siphon body projecting is one of our OEM venture projecting part, Its fundamental portrayal as beneath:

Projecting sort: venture projecting, exactness lost wax projecting

Material: carbon steel, compound steel, tempered steel, aluminum amalgam, zinc composite, metal, dark iron, nodular cast iron, malleable Iron, or determined

Machining: turning, processing, boring, crushing, stringing, CNC machining, and so on Finishing: sand impacting, cleaning, powder covering, Painting, anodizing, Chrome Plating, etc.

Warmth treatment:annealing,normalizing,quenching,tempering,etc. Form Lead time is generally 26 days. Exclusively made by client's drawings or tests. Siphon Parts Casting Applications

Siphon Parts Casting are broadly utilized for water supply system, livelihood of individuals, warming, industry, fire control framework, water system, cooling, cooling, and course of uses.

In the event that you have an OEM investment projecting inquiry contact them immediately.